Eagle Eye Technology:AOI technical expert

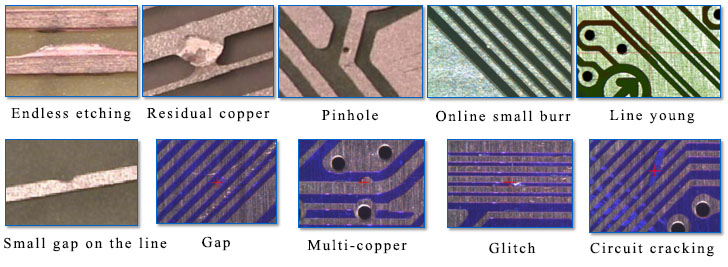

With the further development of electronic assembly to the hybrid technology of Printed Circuit Board with higher density, smaller size and more complexity, AOI (Automatic Optic Inspection) equipment is widely used in high-end PCB industry for graphic quality Inspection. AOI is mainly used to detect defects of PCB in various production processes, such as gaps, sudden copper, short circuit, circuit break, residual copper, pinhole, wire width and wire spacing, etc. AOI is an important means to guarantee the quality of PCB and timely find problems in the previous manufacturing procedure.

Eagle Eye Technology:AOI techical expert

Shenzhen Eagle-eye Online Electronic Technology Co. , Ltd (For short: Eagle Eye Technology) is a proven veteran in AOI technology. Many technical backbones of Eagle Eye Technology are from National University of Defense Technology and they have nearly 20 years’ research and development experience in AOI field. Relying on technical advantages of image precising measurement key labs, the team has mastered excellent AOI detection technologies. Its relevant technologies and achievements won the second prize of national technological inventions, the third prize of China innovation and entrepreneurship competition, and the first prize of AVIC industrial cup. Currently, Eagle-Eye Technology has set up academician expert workstations in Guangdong and Shenzhen as well as Guangdong Intelligent Machine Vision Engineering Technology Center and conducted cooperation of "production, education and research" with National University of Defense Technology, Shenzhen University, Jinan University, Sun Yat-sen University and other first-class universities, which further enhance their technical advantages in the AOI field.

The RapierII-750 CF-VRS-II

After entering PCB industry, Eagle-Eye Technology launched a series of AOI devices, including The Rapier II-750, The Rapier II-450 and The Rapier II-750s, and became a dark horse in the field of PCB special equipment. With unique detection logic and comprehensive optical design, Long Sword AOI can not only detect defects in the inner and outer plates, but also be compatible with dry and wet film detection. With the upgrading and iteration of PCB process, Eagle Eye Technology closely meets industry demands to successively introduce AOI specially designed for HDI (High Density Interconnector) boards, AOI specially designed for FPC (Flexible Printed Circuit) and AOI specially designed for resin plug and holes. It has become a secret weapon for the upgrading of PCB intelligent factory. Eagle Eye Technology aims to become a national brand in AOI field by building military quality with the spirit of craftsman.

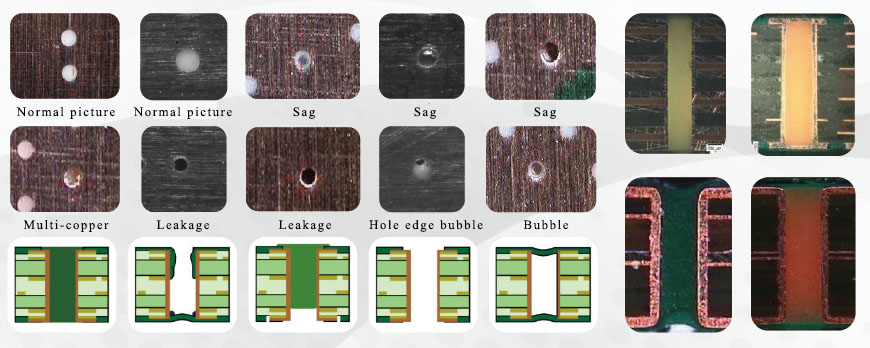

3D vision solves the problem of resin plug detection

With the development of PCB to high density, the blind and buried hole technology of HDI plate is widely used. The resin plug hole, i.e. the blind plug and buried hole of the resin plug, becomes one of the necessary processes for producing HDI boards. Main defects of resin plug holes include leakage, bubble, depression, which will lead to blasting plates, spurious joints and other bad results. There are tens of thousands of resin plug holes on a PCB board and the minimum diameter is less than 6mil (0.15mm). Even if a plug hole is not good, the whole plate may not be used, which poses a great challenge to the detection of the resin plug hole.

The AOI equipment commonly used in the industry can only be used for 2D imaging detection and it can not detect the depth information of the resin plug. Therefore, its detection effect is not ideal. After half a year, the R&D team of Eagle Eye Technology introduced 3D vision on the basis of the original AOI Technology and launched AOI specially designed for resin plug hole. It can detect the depth and defect information of resin plug which cannot be detected by routine AOI, which solved an industry problem. In the comparison test, the data of AOI used for the resin hole shows that it is not only superior to the artificial visual inspection, but also better than the similar imported equipment, which has been recognized by Zhuhai Zhendong and other major resin hole manufacturers. AOI dedicated to the resin plug holes made by Eagle Eye Technology has gradually become standards in the same industry.

National brand serves national industry

According to statistics of Prismark, an industry authority, China's PCB output value in 2017 was $29.732 billion, accounting for 50.52 % of the global PCB output value ($58.843 million). China has occupied half of PCB industry and PCB industry has become the pillar of its national manufacturing industry. The AOI series of Eagle Eye Technology inherits the excellent military industry style of dedication, rigor and hard work of National University of Defence Technology. Each detail is required to be well treated according to military thoughts so that it can meet military quality and have excellent quality. Just like Long Sword AOI's pursuit of "promoting craftsman spirit and creating AOI national brand", Eagle Eye Technology looks forward to joining hands with more PCB companies to add wisdom to smart factories, improve quality for process manufacturing, and share common destiny with PCB industry to promote the rise of Chinese manufacturing!