In the full-scale screen era,Eagle-Eye Technology breaks through difficult dispensing problem

The screen size of electronic products represented by smartphones has been gradually improved to the best. In order to pursue better visual effects and user experience, the overall screen has become a new hot spot in the mobile phone market since 2017. According to the expectation of CINNO Research, an industry third-party consultancy, the penetration rate of overall screens in the smart phone market was 6% in 2017, and that rate will soar to 50% in 2018, followed by a gradual rise to 93% in 2021.

The upgrade of the overall screen involves a number of new design schemes, including narrow frame, special-shaped screen, under-screen fingerprint and micro-camera, which also puts forward many new requirements for the manufacturing process. Dispensing, a widely used process in mobile phone manufacturing, faces many difficulties in the age of full screen. The more demanding precision requirements, the more complex dispensing routes and the diverse ratios of width and height pose great challenges to the dispensing process and equipment.

Precising dispensing realizes super narrow border

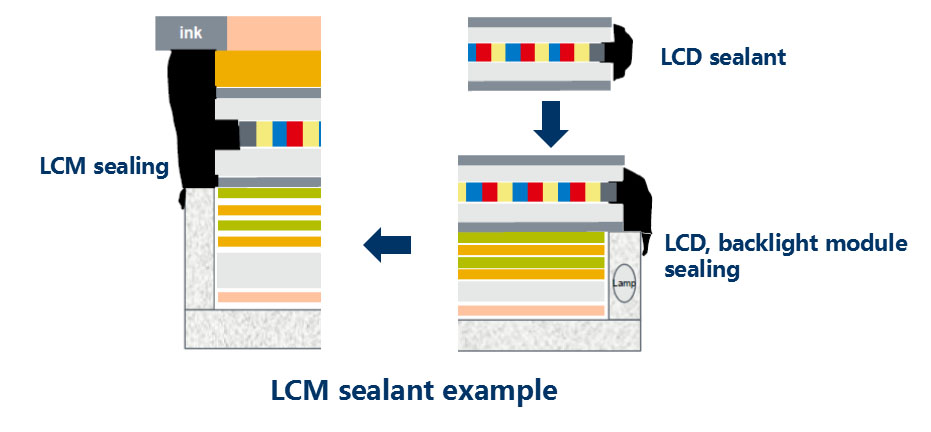

The implementation of full screen needs the maximum reduction of the width of BM (Black Matrix) areas so as to achieve narrow borders and improve the screen proportion. In the super narrow frame scheme, the area left for the frame is only 1.3 mm wide and the area left for the middle frame is only 0.3 mm wide. The original dispensing width is generally 0.5mm, which can not meet the precision requirements of narrow borders. In order to adapt to the trend of the overall screen, Eagle Eye Technology introduced the dispensing machine, which can precisely control and locate the size and width of the glue through the accurate glue quantity control of the injection valve and the dual-intelligent vision localization system. It is used to cooperate in selection glue. The precision of the glue width can reach 0.25mm. It can be applied to the sealing, dispensing, filling and other processes and meet requirements of the ultra-narrow frame solution.

Special-shaped dispensing ensures stable and reliable operations

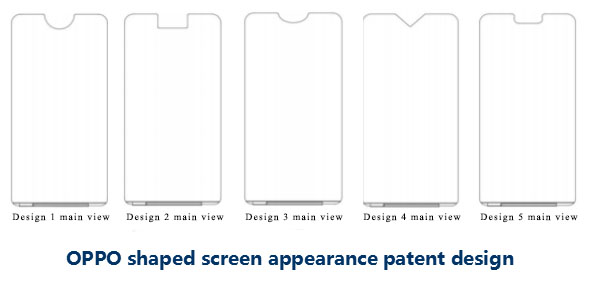

“Special-shaped screen” (Notch screen) is the best solution for full screen at present. On the one hand, due to technical limitations, you need to do a U-cut at the top of the screen to reserve space for front camera, distance sensor, receiver and other elements. On the other hand, in order to protect the screen from impact, it is necessary to cut it at the four corners of the screen to Angle C or Angle R, and increase the reinforcement of the buffer foam so as to prevent the broken screen caused by falling and other impacts. OPPO, for example, has applied for a patent on appearance in 2017. There are as many as five kinds of special-shaped appearances.

The dispensing path of special-shaped screen is more complex compared with that of the traditional rectangular screen. What the irregular dispensing paths bring is not only challenges of motion control, but also a control problem of dispensing quality stability and continuity. In response to the irregular shape and stability requirements, Eagle Eye Technology adopts the precising motion control technology with multi-axis linkage. At the same time, with the aid of smart visual system positioning and navigation, it can achieve the continuous dispensing of any curve path and maintain the accuracy and stability requirements of the quantity, width and ratio of glue.

High width-ratio control+AOI detection makes it a good dispensing tool

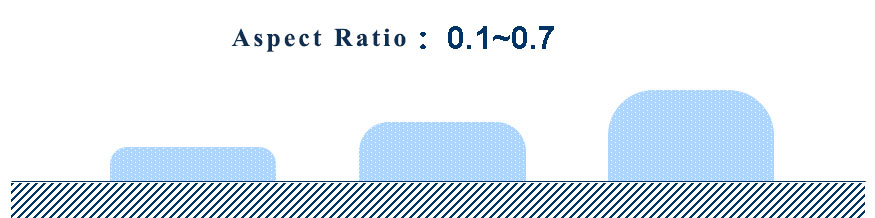

The technical difficulty of dispensing is not only shown in the control of dispensing size and path, but also the control of dispensing shapes. In the mobile phone manufacturing process, there are numerous dispensing scenarios, and different scenarios have different requirements for the ratio of dispensing height and width. Eagle Eye Technology can control the ratio of dispensing height and width in the range of 0.1 to 0.7 through the micro-flow control technology of dispensing valve dispensing valve as well as the unique dispensing molding technology. It is suitable for most dispensing scenes of the full screen manufacturing. AOI (Automatic Optic Inspection) technology can detect dispensing width, path and shape, and control the rate of good products and the quality. This technology becomes a dispensing edge tool in the era of full screen. In the future, Eagle Eye Technology will continue to upgrade the smart dispensing technology, and work together with display panel manufacturers to meet new changes and new challenges brought by the full screen era.